-

Part Deux

The speakers in the end are going to look like GlaDos Eyes. I hoped in the beginning that I could just find some spheres that were the right size and mod them, but I never found anything that looked like it was going to work. I eventually stumbled across this project over at partsexpress.com, which is where I got all the parts for the subwoofer. The project explained how he made the spheres. I calculated that with my 2.75inch speaker drivers that I would want the spheres to be between six and seven inches in diameter. Sadly, I could not for the life of me find a candle mold that size. This of course meant one thing, I get to make my own mold.

I went to Fred Meyer (I hate Wal-Mart) and got a ball. I came home and mixed up some paper mache, which consisted of 1/2 cup flour, 1 cup water, and 4oz of Elmer’s Glue.

I then ripped up the day’s paper and put about five layers on. This was fun and messy.

After it dried I made a template for a rim that would go around the circumference of the sphere.

And cut it out and glued it around the middle.

To add strength as a mold, I then put fiberglass over what I had.

Here are the two halves after the fiberglass and rims are added. They are only clamped together, they are seperate halves. Eventually I will cut a hole in one and it will be the hole through which I slush cast some Tufcal, which is a plaster which is fiber reinforced to reduce chipping. The speakers will eventually be mounted to the plaster spheres.

Next up I have one of the speakers on top of the mold for a size reference. I will compare this to one of GlaDos’ eyes and perhaps you can get an idea of the eventual final product.

-

Re: Part Deux

im watching closely

no point to sub i look at every mod..

-

Re: Part Deux

LOL... awesome.

Glad to see you moving forward with this!

-

Re: Part Deux

haha...nice DARE ruler! You aren't from Ohio are you? Anywho, I longboard as well (only have a Luke Nosewalker at the moment). But back to the thread...this looks cool!

-

Re: Part Deux

I have a landyachtz HD race board with exkate trucks and 80mm cherry bomb wheels. It rides super smooth and has a 6 ft turning radius. I also have an Arbor pocket rocket with 5" Gullwing slalom trucks. My first deck was an Arbor pin with Randal racing trucks.

Cool to see another boarder. I'm from WA though.

-

Re: Part Deux

that's cool....you guys have MUCH better hills I would imagine...my nosewalker has Randal II 180's with Sector 9 72mm wheels...get this though, they're a 65a! like butter!

-

Re: Part Deux

I've been moving to harder wheels lately. I used to go really soft, but I find more and more that I want to power sliiiiiiiide down hills instead of bomb. A fun thing to do (if you can), go to a gym (basketball) with some friends, turn up the tunes, and longboard around. It is really really fun. We call it gymsurfing. It is very Zen, and a good date.

-

Re: Part Deux

My TufCal arrived and I went to slush cast some speakers. Sadly, however, I could not get my homemade mold water tight. I had clamps and vaseline and a shower liner ring cut out to help, but it didn’t work. Plaster spilled everywhere. I was irritated and took a week off to think about things. After that week I knew that if I had neoprine that I could make it waterproof, but I decided that I could go another direction.

I went back to Fred Meyer’s and got two more balls, each one the same size. I then proceeded to fiberglass both balls completely. Each ball would serve as its own mold completely and would then remain part of the final speaker. The ball on the left has not been cut open yet.

The ball on the right was cut open with a 2.75inch hole saw. I removed the ball and glued in some PVC pipe. The plaster will be poured right into the opening. I calculated that ~5 cups of plaster will yield me ~0.75inches of plaster in the inside. That is perfect.

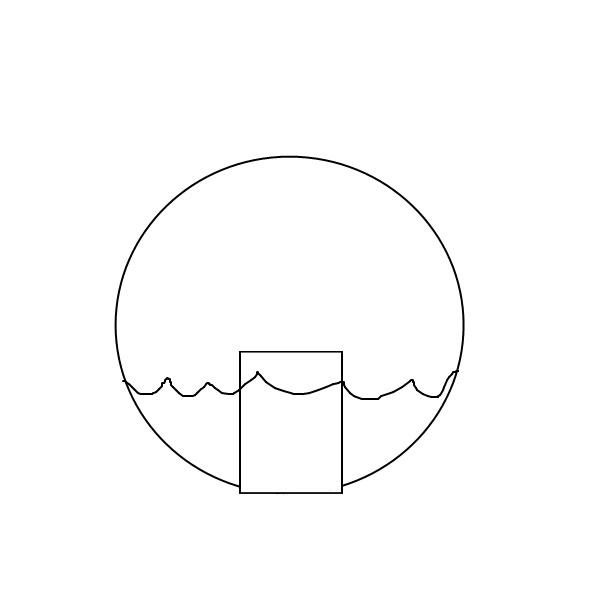

From this point I will be able to pour the plaster right in the opening and turn the sphere without having to seal the hole. The pipe is above the water line, so the plaster will never be able to pour out, even when the ball is upside down. Now I don’t have to worry about making the stupid thing water tight. The plaster will cure as I spin the ball, creating an even coat on the inside. This technique is called slush casting. I made a very fancy diagram showing how the ball can be upside down without spilling the plaster. Don’t laugh . . .haha.

Here is the TufCal. It’s a good plaster and resists chipping because of fibers in it. It cost about $75 shipped for a 50lb bag. I slowly sifted 2.5 cups of plaster mix into 2 cups of hot water, then stirred. About a minute later I poured the plaster into the mold and began to spin. It worked. No spills, just drips. The results were great. It set up in under 10 minutes. Hot water does the trick for a quick set.

Just like normal plaster.

The next two pics show one ball with the plaster cast and set, and one without. The plaster adds a few pounds. I’ll measure later. You know what they say; if it is heavy, it must be expensive!

A closeup of the inside. Nice and even!

After completing one shere, I quickly did the other. It went equally well and I am pleased. The artsy part of this, the fun part, will be equally difficult I fear. From here on out I have to make this thing look good. Wish me luck!

-

Re: Part Deux

u have balls!!! lol

nice work...

looking 4wrd to this...

-

Re: Part Deux