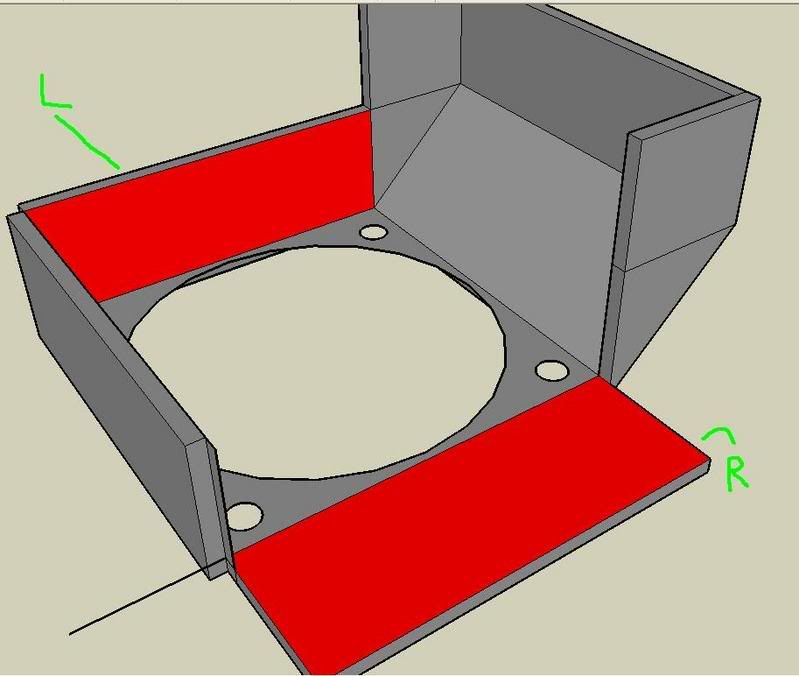

I had a similar issue a while back. Asked my dad, who is an engineer dealing with stuff like this and he said the following:

"..whenever you measure, you always take into account the middle part of the metal, not the inner or outer edges. And when you bend it, you simply draw a circle with the desired turn radius. Of course, the metal should be able to take that strain and not break.''

If you are using a bending contraption, then you too should take the bending radius into account. If your part needs a desired width, then take that into account and make the bend and straight part so that the external width is what you need. If you have something fitting inside the part, and the fit is gonna be on that side, then the bend will be in the exterior. So, you can either extend the bend or not.

Drawing stuff in 2D helps with the understanding of the process.

EDIT: I take too long to type.. message is mostly above. Remember, buy extra materials in case you screw up. For a nice long read about bending, try tribal's log, blackout

Reply With Quote

Reply With Quote