Hey all. I figured that I've been lurking long enough, and that I should actually contribute something. Therefore, I have been taking pictures of my current project with the aim of making a worklog. The purpose of this project is to build a frontend for my networked media server. It is a Linux machine running the Mythbuntu operating system. This allows me to have all of my music, videos, etc on a remote backend accessible from simple machines hooked up to my TVs.

This particular unit is the one for my living room TV. The challenge here is that I need to make it as small as possible (so that it doesn't intrude) - but at the same, I'm stuck using spare parts that I have around to keep cost down. This means a full ATX board, and non-slimline parts. Thankfully, I don't need an optical drive, so that cuts down on a lot of space.

Unfortunately, I do not have a picture of the case that I'm using parts from, as it was one I long ago tore apart. Here is a picture I found on google:It is an old Dell box that a lot of offices and universities used to use, which is why I like them: They're easy to find when they get thrown out.

On to the project.

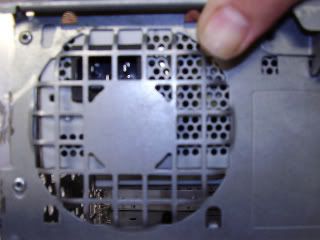

I cut the internal section of the case down to make the tray for the motherboard.

I saved some other parts of that case and another, identical, one that I had lying around. These will be used for the other two sides of the case.

Around this point, I remembered why I hate to clean my workspace between projects: I can't find anything. It took me about 20 minutes just to find my speed square.

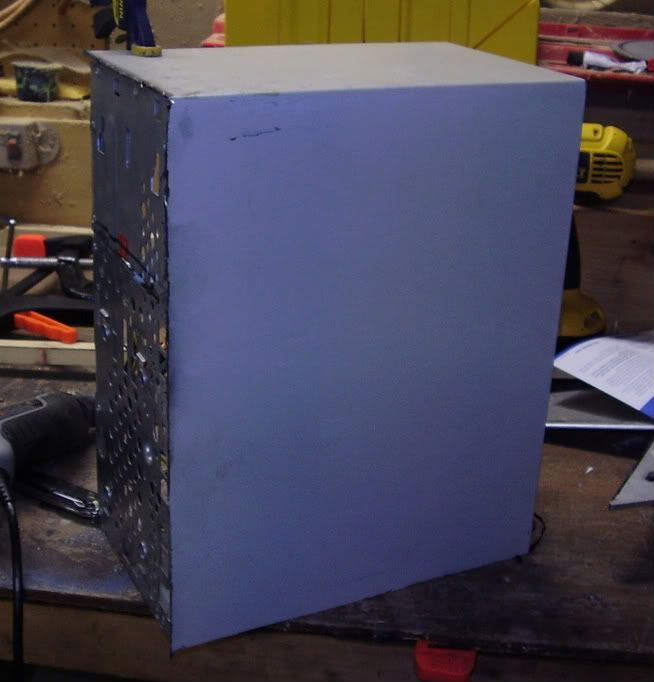

Once I located it, it started lining up parts and mark them out for the sides.

Not being one for welding or such, I am a huge fan of pop rivets. They are an easy, secure and sturdy way to affix pieces of metal. Just drill, stick in a rivet, and crimp it down.

At this point, I had two and a half sides. The next step was to put together the rest of this frame.