Back in the early winter I was commissioned to do a built for a customer who was replacing a very old P4 based system. As near as we could figure their old system was 7 years old and it wasn't cutting it anymore.

Old system:

P4 1.6GHz 478

Asus P4B800

512MB 133MHz RAM

ATi Radeon 7000VE

40GB Maxtor

160GB WD

17" Samsung CRT and 15" Dell LCD

New system:

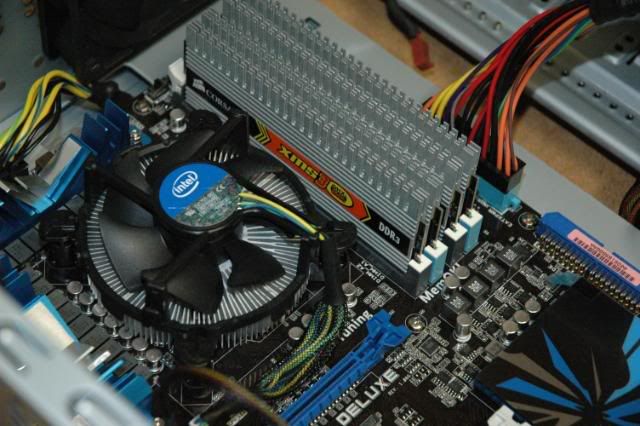

Core i7 860

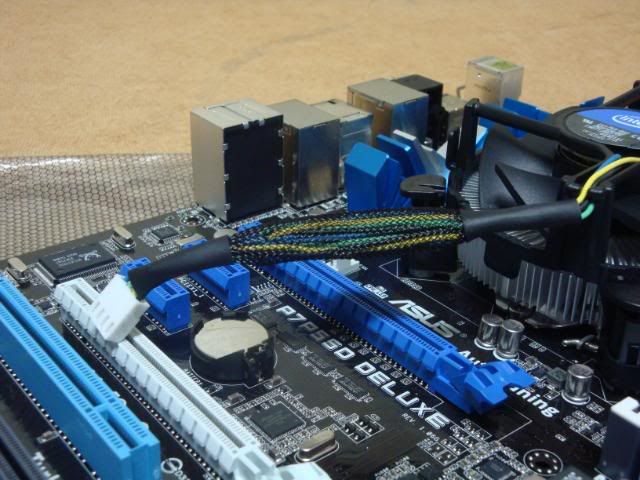

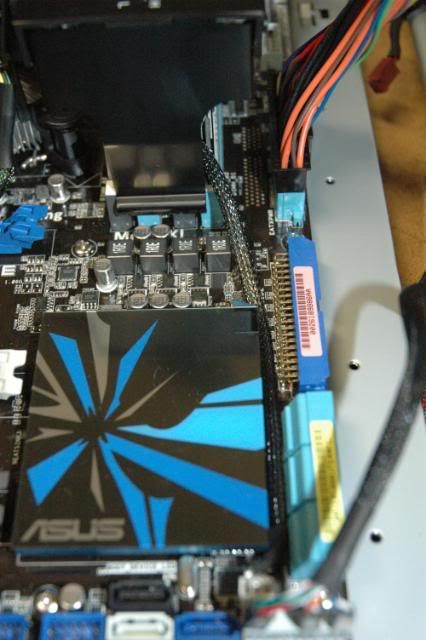

Asus P7P55D Deluxe

8GB Corsair XMS3 DHX heatspreader RAM

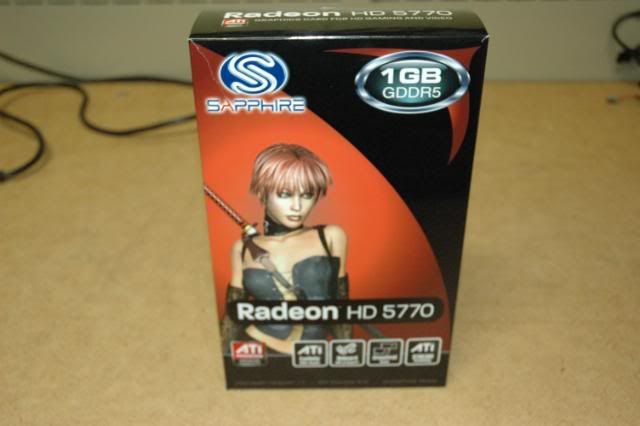

Sapphire HD5770

60GB OCZ SSD

1.5TB WD Green

Hauppauge WinTV HVR-2250

OCZ 750W GameXStream

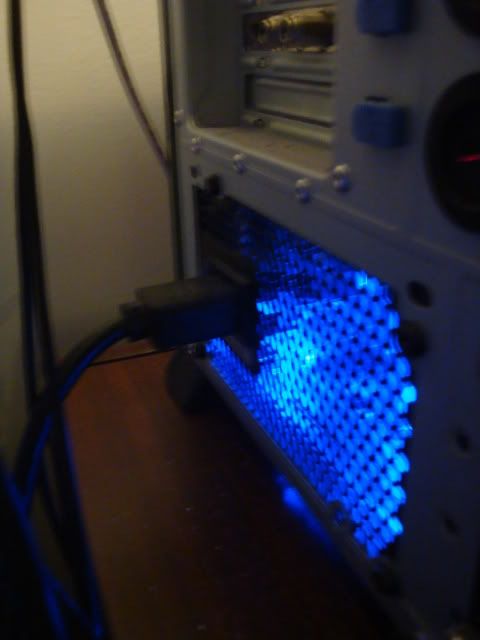

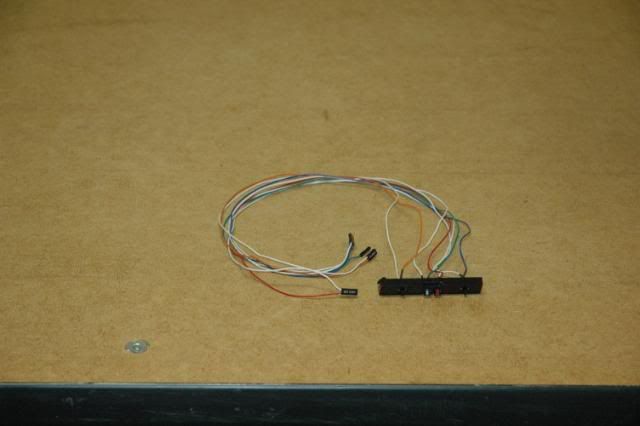

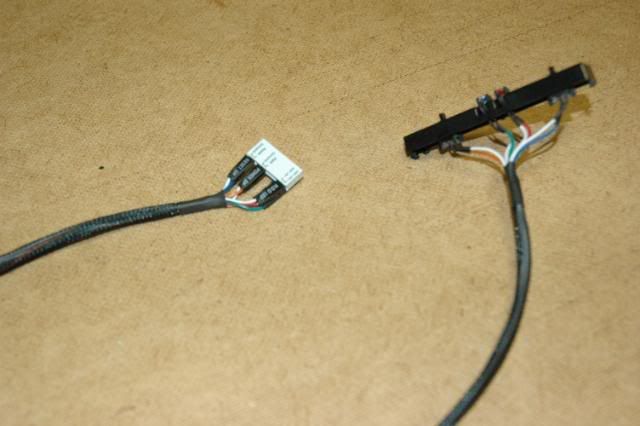

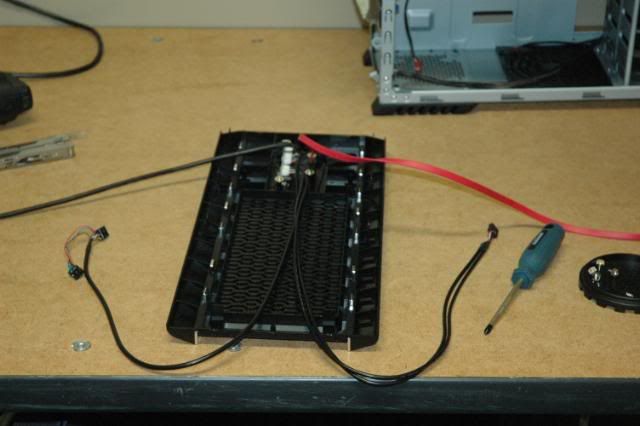

Coolermaster CM690

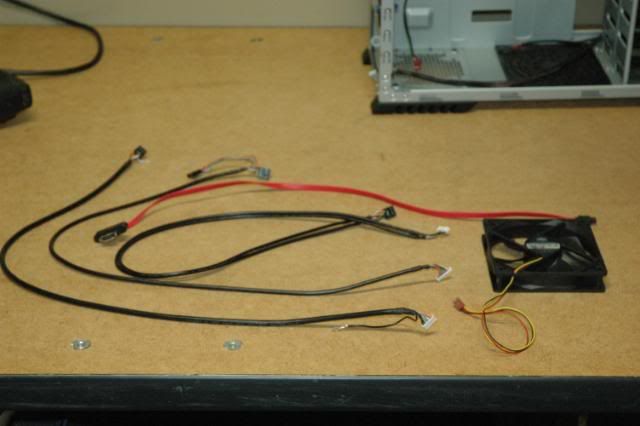

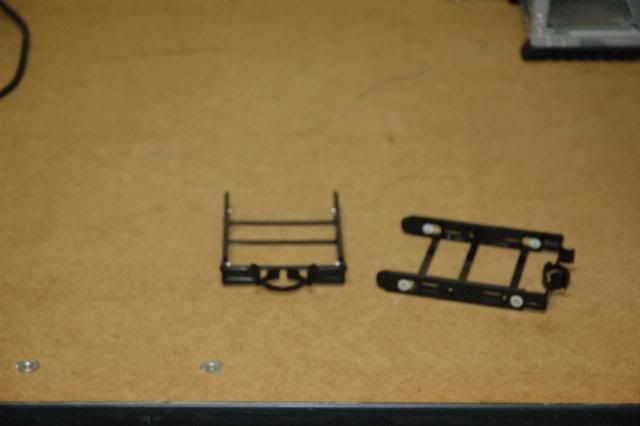

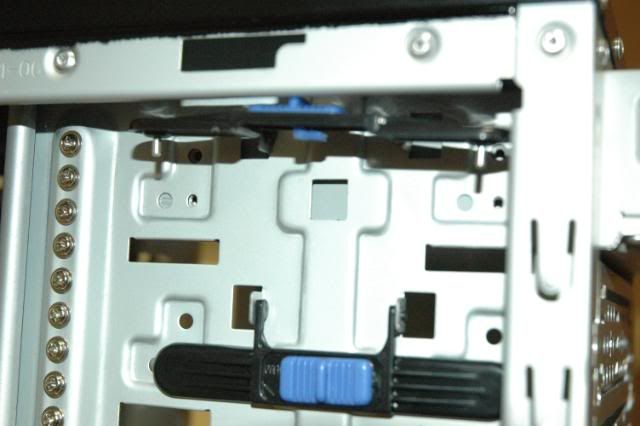

This is the first system I have built all at once rather than through a process of upgrades so there were a few things I was looking forward to doing. First, cable management was of highest priority and every possible wire would be sleeved (with one exception which I'll cover later). Secondly, it meant that I would get a chance to modify the case prior to putting in the hardware.

* Note * Comments are appreciated however this system has been completed and delivered to the customer so changes I can make are limited.

Here's a teaser of all the hardware.

.

.