It is time to start one more little project to do before I continue with the Time Machine.

As you can see by the name it is yet again inspired by the characters in Peter F. Hamiltons The Night's Dawn Triology. For those of you who has read the books knows that Tranquillity is a big space habitat with roughly a cubic kilometre of brain matter.

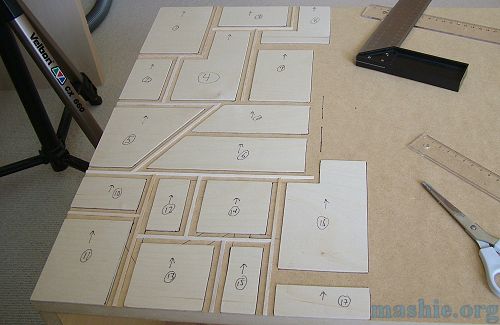

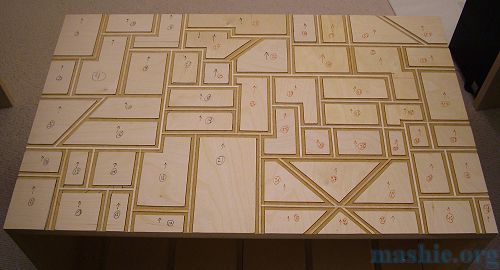

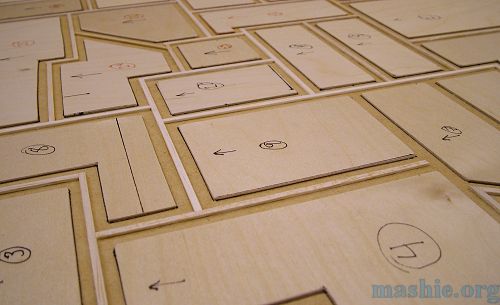

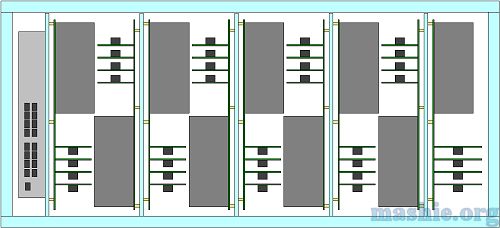

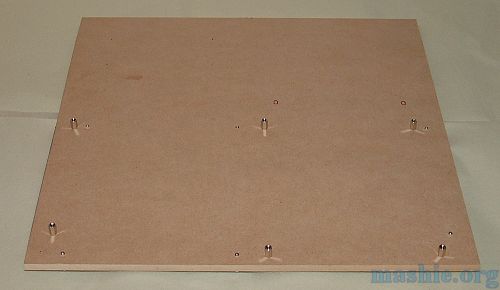

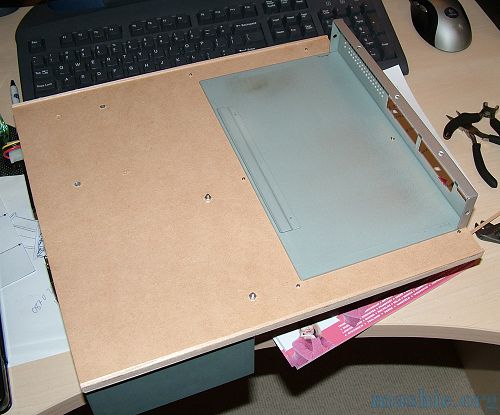

That is where all similarities ends though. Tranquillity here will be used as some kind of router lab by friends in need so it will have 9 motherboards and 30+ network cards in the smallest possible volume. The construction material will be MDF so a good exercise before starting the work on the Time Machine.

Anyway, time to get the work started.

ModCam status:

It will have to work with seven systems for now and then later on the mobos will be replaced.

It will have to work with seven systems for now and then later on the mobos will be replaced.