Originally Posted by

XcOM

Different solder diameters are produced, too; 20-22 SWG (19-21 AWG) is 0.91-0.71mm diameter and is fine for most work. Choose 18 SWG (16 AWG) for larger joints requiring more solder.

Another tip, if you only have the thin solder available and you need to make a larger joint. Rather than buying thicker stuff for one task, you can take multiple strands of the thinner one and twist them together.

Excellent guide, but I feel there's something missing. The guide centres around soldering components to pcbs, whereas I imagine the majority of modders will be dealing with extending fan/psu wiring, mounting remote CD/DVD buttons, extra LEDs, that kind of thing.

Here's a tip from an old hand...

When stripping stranded wire, don't remove the insulation before twisting the strands. Instead, slide it part way and 'unscrew' it. That makes the resulting twist much neater and it's easier too.

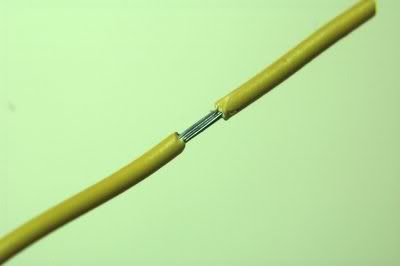

The wrong way, it's difficult to twist when it's like this:

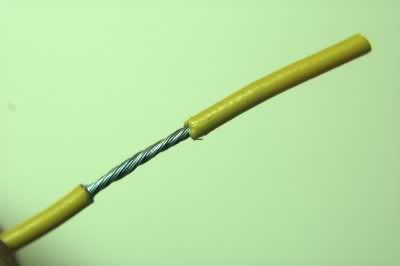

Pull the insulation part way:

Start to twist it:

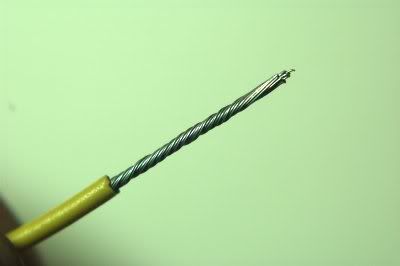

And unscrew it completely:

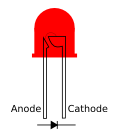

Another tip, regarding LEDs. If you solder right up to the body, you run the risk of damaging it through excess heat, so solder at the end of the lead if possible.

And here's another. If you're using wire cutters to strip the wire (who hasn't?  ) turn them round.

) turn them round.

By that, I mean look at the jaws, one side is usually angled more than the other. If you use them one way the angle will tend to squeeze the insulation onto the wire, making it dificult. The other way they're more likely to push the insulation rather than squeezing.

Code:

wrong:

|/

==--====

|\

right:

\|

==--===

/|

Is that clear? \| are the cutter jaws, = is insulation, - is bare wire. Cutters are moving from left to right.

Originally Posted by XcOM

) turn them round.

Reply With Quote

Reply With Quote