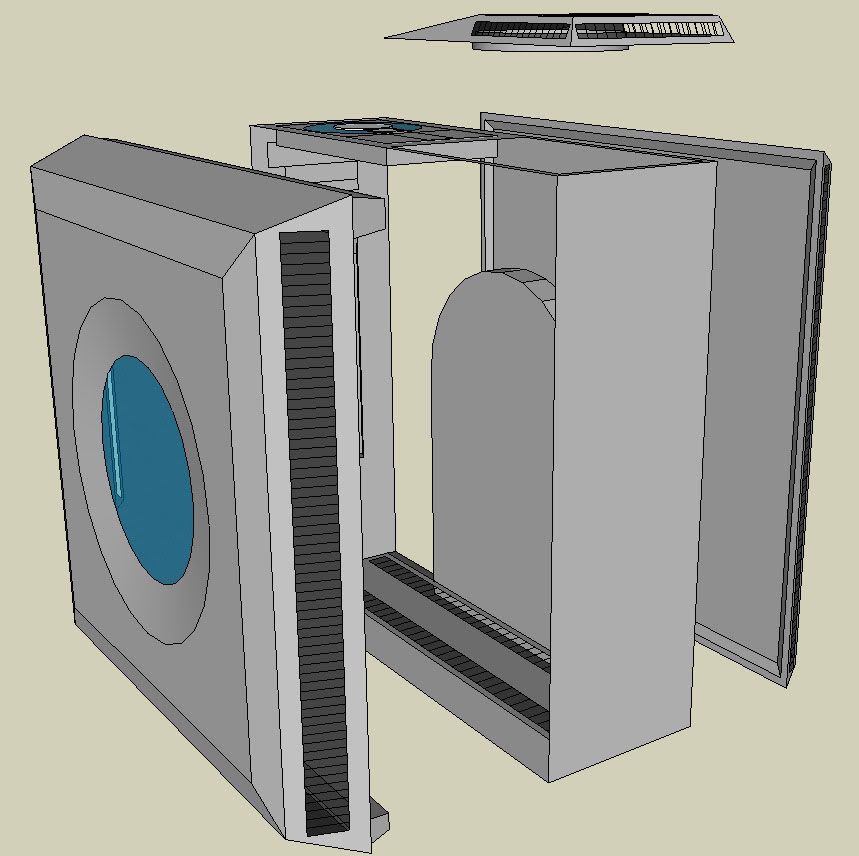

hey, you guys are in luck, im done!!! and if i do say so myself, i have thought up one slick looking case. ill get right to it.

so first, the colours. anything that is blue will be tinted blue acrylic with some super bright whites behind it, or if i cant find any blue acrylic, it will be clear acrylic with blue lighting. anything that is grey will be aluminum. the materials are subject to change though. if i can get my hands on some copper, ill throw that in too, and ill probably throw some styrene in there too. ill figure the materials out as i go....

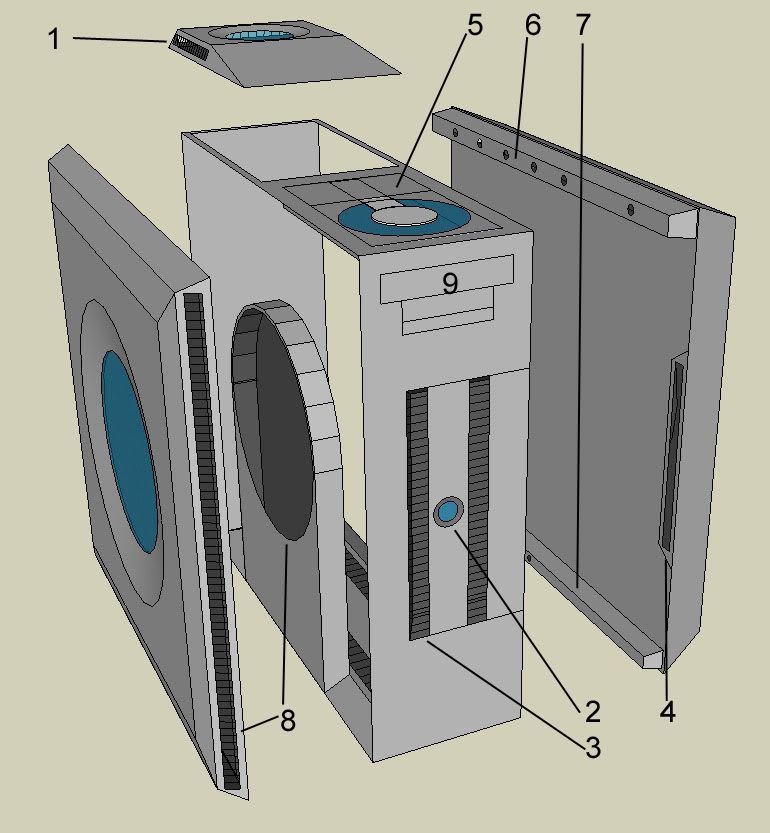

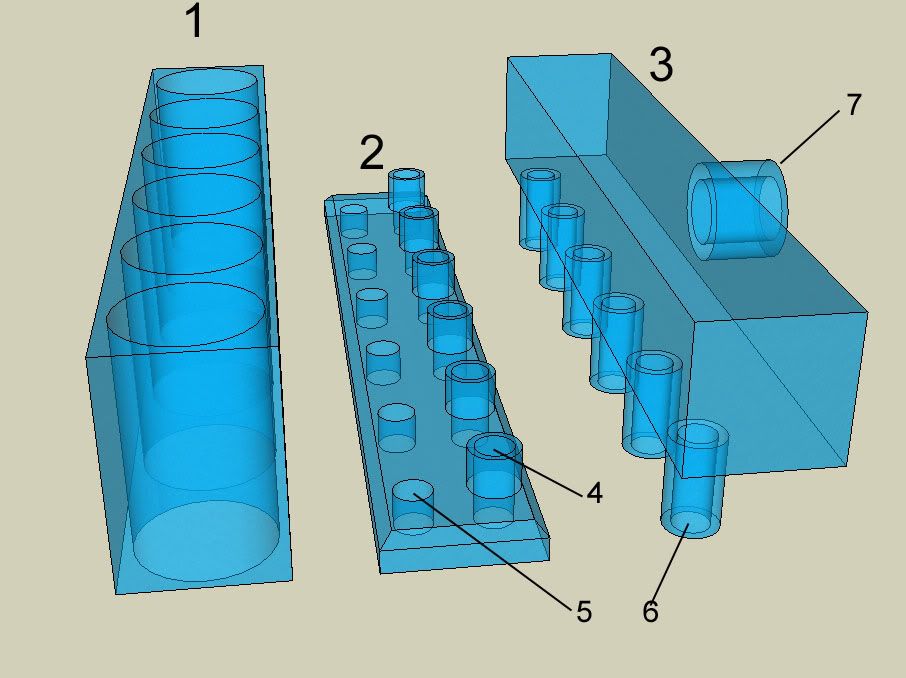

and the numbers:

1. case air exhaust shroud

2. power button

3. water cooling air intake

4. air entry to water-wall (that whole side is going to house a large radiator)

5. a modded top loading optical drive of some sort (as luck would have it, i think my dvd rom just packed it in, so i can practice modding it first)

6. water cooling hot water input

7. water cooling cold water output

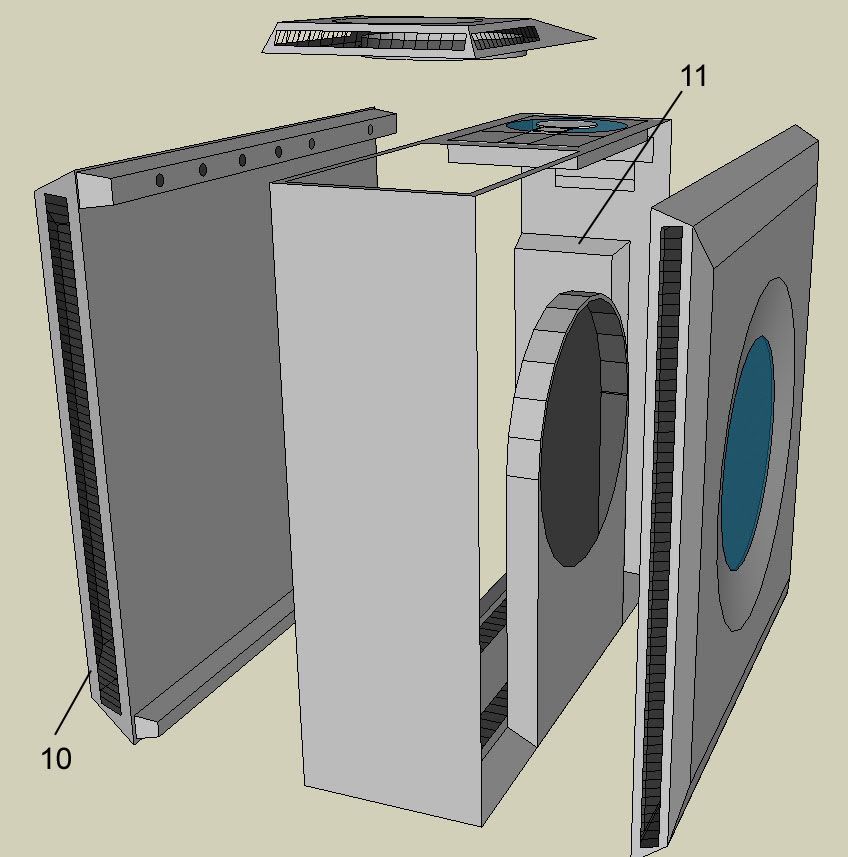

8. case air intake (the left hand wall) and air transfer (the air goes into that large circle thing, down, and then up out of the floor of the case)

9. a 5.25" bay, a floppy bay, and peripherals

10. water cooling air exhaust port

11. the watercooling intake housing (rear view)

so if you can gather from these pictures, its definitely going to be clean and organized. ive got case air and water cooling air separated, and (logically) routed to minimize turbulence (hopefully).

the case air goes in the left hand wall, down to the bottom, then out a set of vents, up though the case, and out the rear of the top. it will be pushed by the largest fans i can fit in there (modded fans of course, i dont want too much noise, and i dont want the square housing they come in). theres going to be a large network of air filters and chemical dessicants in the left hand wall, and that is why im using such a large area just for the intake. it will reduce resistance.

as for the water cooling air supply, it goes in the front vents, into the right hand wall, does its stuff in the wall, and then out the back of that right hand wall. and again, it will be pushed by big modded fans. there will be air filters for the air intake here too, but no dessicants, because moisture wont matter to me if its in the radiator area. if anything, a little condensation (if any) will evapourate and help cool.

now, you may be looking at numbers 6 and 7 (the input and output to the radiator) and wondering why there are six holes in the top one and only one hole on the bottom. the answer is a stroke of genius in my opinion. this is going to be a 6-loop cooling system. there will be a dedicated loop for the CPU, one for the GPU, one for the RAM, one for the chipset, one for the other internals (hard drives and anything else i add), and one lone redundant cooling loop that cycles directly through the radiator again to further cool (i could also use this as a spare if i ever add another piece of hardware that needs good cooling). so each device sends its hot water to the radiator, and once the water has cooled, it comes out in one lone tube at the bottom, heading for the pump. this brings up another question... how am i going to pump all this water?

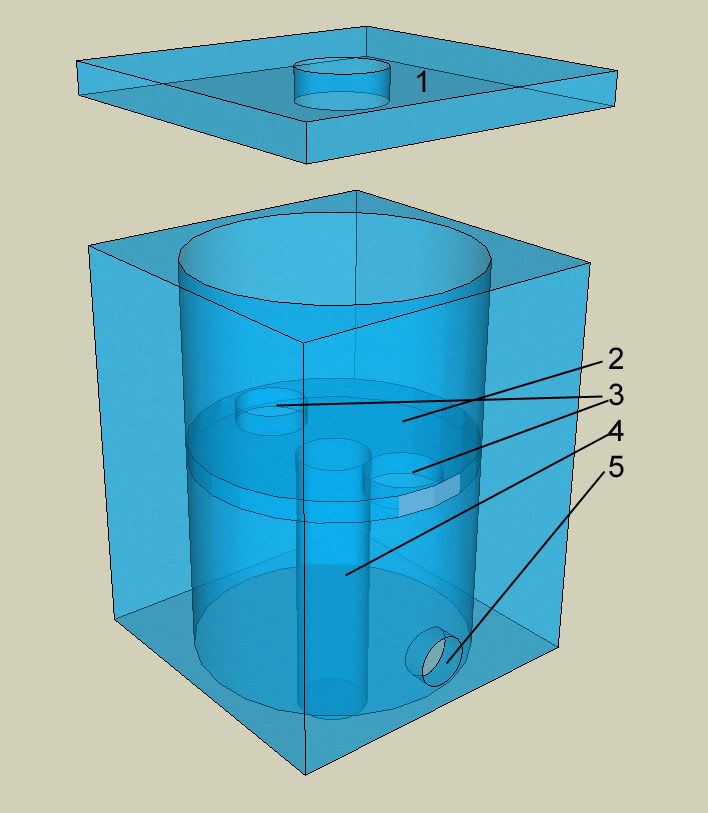

the pump answer is another stroke of genius. there will be one large motor that powers an acrylic version of a straight-six motor. there will be one cylinder for each loop, and that will allow for a dependable flow and pressure for each loop. yes, this means the water will travel in pulses, but i may make it a two-way design where as water is pushed out one end, it also enters the other end... we'll see, it may be hard to do. if i cant make a two way pump, ill just make the cylinders large.

at this point, i havent been able to make up a 3D design of the water pump, or a schematic for how ill run the cooling pipes. ill be working on that over the next week. i cant spend a lot of time on it right now because not only do i have these damn projects, i have two midterms this week, and one next week.

so anyways.... comments? questions? suggestions? criticism? anything? i realize this is very ambitious... but i need to make up for my zanzibar failure... thats my only defense for that.

Reply With Quote

Reply With Quote

make a sketch

make a sketch