i was thinking about 3 side by side to get 6. its a possibility, but it adds a little bit of complexity. im not quite there yet... my thoughts progress to things like that over time, but a week isnt enough. im sure ill eventually be talking about some sort of W-motor.... thats actually not a bad idea... a W-motor (i cant remember the name, but its got three cylinders 30 degrees apart instead of 2 at 90 or 60 degrees). see, ill get there, just give me a few more days to think things through.

now, remember i said i had some ideas to simplify and downsize things?

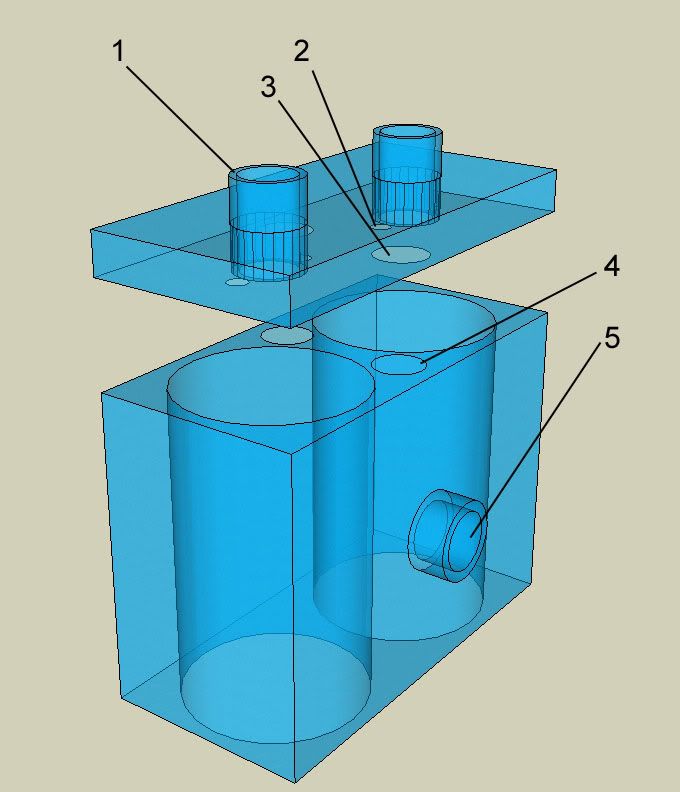

numbers:

1. output, water goes out from here, each cylider has one, and each one has a valve

2. cylinder input, just a hole, no valve, ill probably have more than two per cylinder to reduce resistance

3. hole to make a route between the cylnder block and the top block

4. same as number 3, 3 and 4 join up

5. master input to the cylinder block

ok, i think this may be the best design yet. ill walk you through it. water comes in from the radiator, and goes into the master input, and into the cylinder block. the cylinder block will be made of tubes inside of a box, so there will be space for water to be in there, and not just in the cylinders (this is because the cylinder block will act as a reservoir too). so the water is in the cylinder block, and it travels up through numbers 3 and 4, to get into the top block. the top block also acts as a small reservoir. once the water is in the top block, it goes through the cylinder inputs, and then gets pumped out of the output. one thing i did realize while writing this is ill need walls in the top block to separate each cylinder, or they'll just start transferring water to each other within the pump, and nothing will actually come out.

so this works out to a fairly simple design with the least number of moving parts yet. one master input with a valve, and 6 outputs with vavles... 7 valves. compare that to my first design (12 vavles) and my two stroke crap design (24 valves at the very least) and we have a clear winner so far.

ive got the efficiency of flow pretty much down in my mind now. ill start working on actual cylinder layout now. there are a few ways to do this, and it all depends on what uses the least moving parts again.

Reply With Quote

Reply With Quote

)

)